In manufacturing environments where adhesives, sealants, and specialty chemicals are processed, product recovery can be a huge challenge. The Shar Plunger system addresses this issue by efficiently evacuating high-viscosity products from mixing vessels that wouldn't otherwise flow out easily. Using a combination of hydraulic power and pneumatic sealing technology, the system helps recover material from mixing tanks, reducing product waste while supporting more consistent batch production.

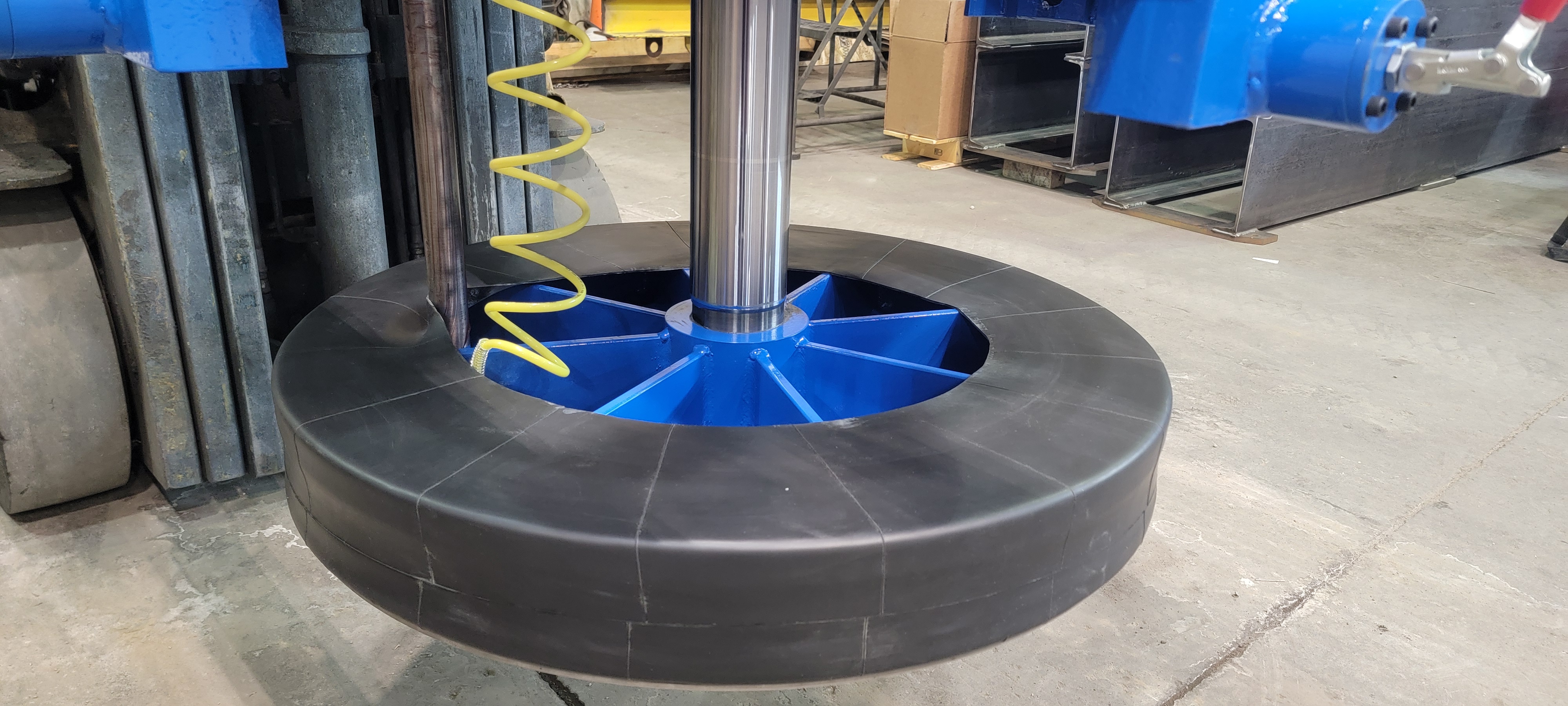

The technical design of the Shar Plunger demonstrates its industrial capability. At its core, the counter-balance valve technology keeps plunger movement stable throughout operation, helping prevent drift during the discharge process. This stability contributes to operator safety and more reliable material discharge. The pneumatic air-seal creates an effective barrier between the plunger and vessel wall, reducing material bypass and improving product evacuation from the tank.

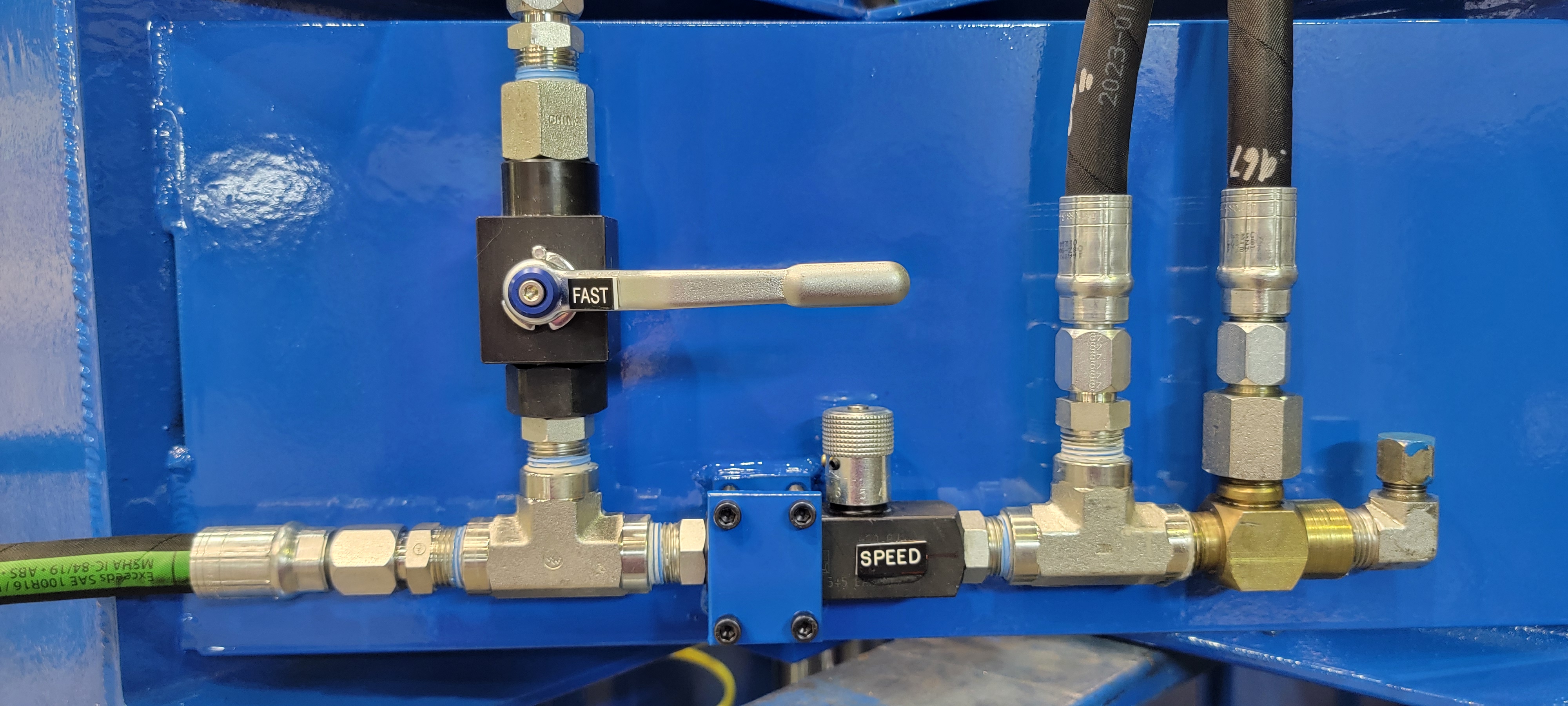

Beyond basic material recovery, the Shar Plunger delivers practical operational advantages. The hydraulic power unit provides control over material flow rates, allowing operators to adjust discharge speed based on specific processing requirements. This control is particularly useful when handling sensitive compounds or when feeding filling systems that benefit from consistent material delivery. The design accommodates various material properties, helping maintain predictable production schedules even as formulations become increasingly complex.

The Shar Plunger incorporates important safety features, including protective guards, locking pins, and limit switches for operator protection. The hydraulic components are selected for reliability in production environments, while the self-contained design simplifies maintenance requirements. When paired with Shar-fabricated tanks, the system creates an integrated solution that can be adapted to specific production needs, enhancing both material utilization and manufacturing efficiency.