Products

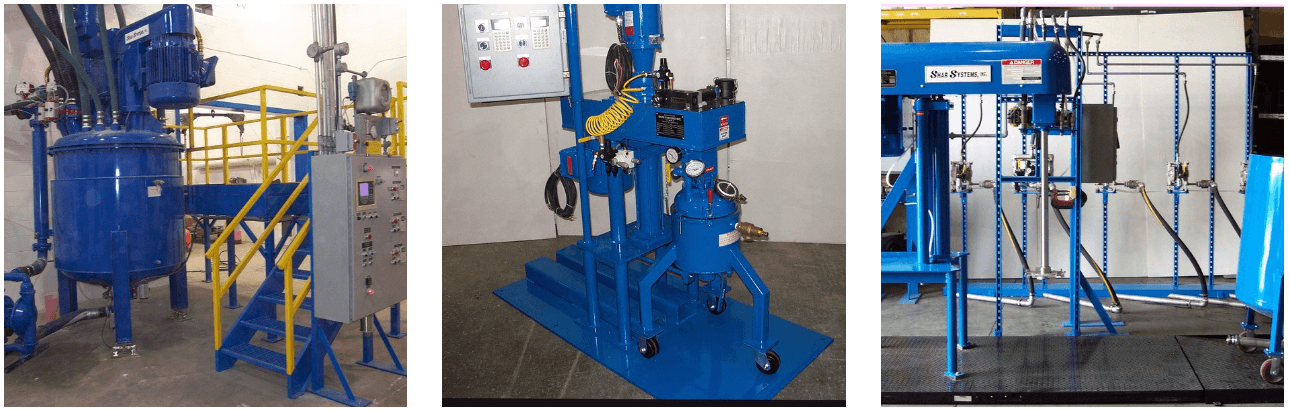

TANKS

Our extensive portfolio showcases our expertise in creating custom tanks to meet your specific requirements. We fabricate tanks out of:

- Carbon steel

- Stainless steel

- Aluminum

These tanks can have dished, flat, or conical bottoms and are available as non-pressurized vessels, pressure vessels, single-wall designs, or jacketed designs. They can hold liquids, solids, or a combination, with capacities ranging from 1 gallon to 10,000 gallons.

If a specific process requires a plastic or fiberglass tank, we can custom-manufacture them to work with our equipment. Our team will work closely with you to fabricate a tank solution tailored to your unique needs, whether for a particular industry or application.

MIXERS

Shar Systems can provide slow-speed mixers up to 200 horsepower. Our mixers are equipped with different types of impellers and can be constructed with various materials to suit specific atmospheric, vacuum, or pressure applications. We also provide both fixed and variable speed options, with speeds ranging from 15 RPM to 9,600 RPM.

Our mixer offerings include:

- High-speed and low-speed models

- Single-shaft or multi-shaft configurations

- Hydraulic lift, airlift, and tank-mounted designs

- Belt-driven, direct-driven, and gear-driven models for vertical or horizontal mounting

- Non-explosion proof and explosion-proof environment capabilities

These mixers can handle liquids, solids, or a combination of materials. All units can be customized to fit your unique requirements, whether for adhesives and sealants, aerospace and aviation, batteries and electronics, chemicals, cosmetics and personal care products, glass, cement, ceramics, inks, paints and coatings, pet food and animal health, or plastics and composites.

Our team will work closely with you to provide a tailored mixing solution specific to your industry and application needs.

DISPERSERS

Shar Systems can also provide high-speed mixers up to 300 horsepower with various types of impellers, and materials of construction, with fixed or variable speed options as needed for atmospheric, vacuum, or pressure applications.

BATCHING SYSTEMS

Completely automated batching systems that can handle up to 60 liquid or dry component additions, automatically controlling mixing time and speed, dust collection, tank cleaning, vacuum, and temperature sensing. We also engineer semi-automated filing systems to package your finished product.

AGITATORS

Agitators are mixing devices used to blend and stir solutions in tanks and vessels across various industries including mining, manufacturing, wastewater treatment, and more. Shar Systems and Deister Concentrator have teamed up to offer American-made agitators ranging from 1⁄4 to 300 horsepower for use in mining applications as well as other industries requiring custom heavy-duty mixing solutions.

MISCELLANEOUS EQUIPMENT

Shar Systems also can design and fabricate tank cleaning systems, platforms, piping, conveyor systems, and tank plungers, among other custom-designed equipment. Systems can also be built to incorporate other manufacture’s components such as dust collectors, vacuum pumps, heating systems, and many more.

TURNKEY SYSTEMS FROM SHAR

There are two ways you can go about updating or expanding your liquid or semi-liquid production line. You can hire one company for the conceptual design and drawings of a production system. After the planning phase, you will have to coordinate numerous contractors for the installation of the various components. Then you will have to hope that your job will be completed on schedule without holding up your production longer than necessary, or you can call Shar Systems.

Shar Systems strives to simplify your workload. All you have to do is tell us the formula of your product and how much you want to produce, and we take responsibility from there. Our team will design and install your system, furnish the necessary drawings, conduct comprehensive testing, and even train your employees on how to use it. The best part? All of these services are already included in the cost of your equipment. At Shar, we offer you a competitively priced mixing system that comes with free engineering services.

Choose Shar Systems for a hassle-free experience and peace of mind.